machinery & equipment for sale

items for sale

Forklift

Hydraulic Guillotine

200T Hydraulic Press

Metal Cutting Band Saw

Curving rolls

Metal Printer-Engraver

Air Compressor

Spot Welder

Manual Panbrake

Pedestal Drill

Air Receiver

TIG & ARC Welder

Hand Lever Shear

Pedestal Buffer

Bench Grinder

Shrinker Stretcher

Bench & Offset Fabricated Vice

Forklift Jib Attachment

HG-440B – Hydraulic NC Guillotine

MINIMAL USE – 1 ONLY

- 1300mm x 4mm cutting capacity

- 5.5kW / 7.5hp 415V motor

- Ezy-Set NC-89 Go-To digital display controlled backgauge with DRO counter

- Quick action blade clearance adjustment for shearing material 1 – 4mm

- Hydraulic material clamping for accurate shearing

- One shot lubrication pump & reservoir for slideway protection

- Blades made from 9CrSi material suitable for cutting stainless steel

- Plate support tables with transfer balls for quick & easy material alignment and manoeuvrability

- Front sheet supports with ball bearing guides preventing material damage when setting up

- Safety three photo electric light beams on rear guarding

- Safety reset rear guarding button mounted to back of electrical box

- Heavy duty under driven machine construction

- Equipped with shadow line lighting-alignment device

- Roving foot pedal control

- Mild steel capacity is rated on hot rolled material with 250MPA

- Pre-Commissioning:

- 1. Guillotine is run & tested prior delivery

- 2. Hydraulic oil is included with machine

200 tonne INDUSTRIAL HYDRAULIC PRESS

NEVER BEEN USED – 1 ONLY

• Easy to use and powerful press for most applications

• Ideal for the repair of axles, shafts, & press fit of bearings & bushings • Ram speed down 6.7mm/sec, returns 5.0mm/sec

• Heavy duty welded steel fabricated frame

• Strong hydraulic cylinder ensures precise pressing during operation • Fitted with pressure gauge

• Safety overload valve

• Hydraulic joystick control lever

• Powerful TEFC motor

• Heavy duty one piece table plate insert

• Extra heavy duty table support with high tensile setting pins

• Table can be adjusted for height using chains and Hydraulic ram • Pre-Commissioning:

• 1. Press is run & tested prior delivery

• 2. Hydraulic oil is included with machine Includes

• Includes support plate & V blocks

BS-13DS – Semi – Automatic, Swivel Head-Dual Mitre Metal Cutting Band Saw

NEVER BEEN USED – 1 ONLY

- 458 x 235mm (W x H) rectangular capacity

- Double mitre swivel head for easy angle cutting without moving material

- Semi-automatic operation, machine returns to open height position after finishing the cutting process

- Automatic hydraulic vice incorporated with a manual hand wheel

- Adjustable hydraulic vice pressure regulator

- Hydraulic operated system raising and lowering the cutting beam

- Adjustable hydraulic feed cutting rate for multiple applications

- Blade breakage sensor fitted that automatically shuts machine off

- Mitre cuts to 45o right & 60o left using swivel head

- Built-in coolant system for maximum cutting efficiency with wash down trigger

- Laser line guide assist in lining up material positioning

- Adjustable variable blade speed system enabling 19-102mpm cutting speeds

- Limit switch stops machine and raises cutting beam when cut is complete

- Swivelling electric control panel mounted on base for quick operation

- Combination roller bearing & carbide blade guides

- Heavy duty cast iron blade wheels

- Large mitre scale – easy to read

- Cast Iron frame with heavy duty fabricated base

- Adjustable blade roller guides provides accurate cutting

- Adjustable length stop for repetition cutting

- Wire wheel brush to clean swarf from blade

- Industrial-duty gearbox driven by a 1.5kW / 2hp 415V motor

PR-133 – Motorised Plate Curving Rolls

MINIMAL USE – 1 ONLY

- Initial pinch rolls with pre-bending

- Two rolls powered by gearbox drive system

- Swing out top roller enables cylinder to be removed

- Safety wire interlock system with emergency shut-off

- Precision ground rolls with wiring grooves

- Includes a conical bending guide roller

- Mobile foot pedal control

- Mild steel capacity is rated on hot rolled material with 250MPA

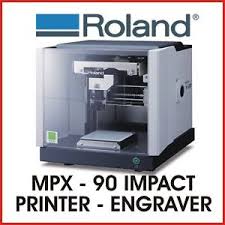

ROLAND MPX-90 ENGRAVER & IMPACT PRINTER

NEVER BEEN USED – 1 ONLY

Printable material: Gold, silver, copper, platinum, brass, aluminium, iron, stainless steel (Vickers hardness [HV] of the printing surface must be 200 or less.)

Loadable material size:

Maximum 100 mm (width) x 200 mm (length) x 40 mm (thickness) [3.9 in. x 7.9 in. x 1.5 in.]

200 mm (width) x 100 mm (length) x 40 mm (thickness) [7.9 in. x 3.9 in. x 1.5 in.]

K30SI – Silenced Air Compressor

NEVER BEEN USED – 1 ONLY

Maxx Pressure (PSI): 174

Max Pressure (kPa): 1200

Features

- Steel cabinets lined with acoustic foam to deaden noise and maximise cooling air flow

- Thermostat-controlled cooling fans combined with over-temp. protection ensure correct operation

- K-Series db(A) ranges approx. 63 to 68

4640-16 – Industrial Pedestal Spot Welder

MINIMAL USE – 1 ONLY

16kVA

Maximum welding thickness (mm): 2.5 + 2.5

Maximum welding power (kVA): 35

- Adjustable electrode stroke

- Water-cooled transformer, arms and electrodes

- Adjustable electrode force; a micro switch starts the welding cycle when the desired pre-set value is reached

- TE101 TECNA MICROPROCESSOR CONTROL UNIT:

- Synchronous thyristor drive with phase-shift control for welding current adjustment.

- Built in ammeter (RMS value), 2 selectable ranges (18-56 kA).

- Storing of 99 welding programs.

- Inputs for external selection of 31 programs or 15 programs with parity control.

- Welding times adjustment in half-periods.

- Pre-weld, slope and pulse functions.

- Welding current control limits. Error condition signalling output and function to stop welder operation.

- Single and repeat operating mode. WELD/NO WELD function.

- Welding current compensation function to assist welding of oxidised sheets and rods

PB-416D – Manual Panbrake

MINIMAL USE – 1 ONLY

1260 x 1.5mm Mild Steel Bending Capacity

- “NO BULL CAPACITY” – Australian Tested & Rated To True Working Capacity

- High quality finish

- Robust steel fabricated construction

- Foot clamping, allowing material to be positioned & clamped at the same time

- Ideal for schools, bending is assisted by heavy duty telescopic springs

- Removable individual bending fingers for pans or boxes

- Mild steel capacity is rated on hot rolled material with 250MPA

PD-35 – Industrial Pedestal Drill – Belt Drive

MINIMAL USE – 1 ONLY

Drill Capacity (mm): 31.5

Spindle Taper (MT): 3

Spindle Travel (mm): 125

Throat Depth (mm): 225

- Quick action belt tensioning lever

- Adjustable safety drilling chuck guard with micro switch

- Safety micro switch on pulley guard

- Safety magnetic-type switch & emergency stop switch

- Rack & pinion table height adjustment with locking lever

- Thick walled column ensuring greater rigidity

- Table tilts left & right to 45o & rotates 360o

- Drilling depth stop setting with scale

- 9 Spindle speeds – 180, 300, 320, 310, 430, 480, 620, 1050, 1200, 1680rpm

- 240V Fan-cooled motor rated for continuous use with overload protection

3100150 – Industrial Vertical Air Receiver

NEVER BEEN USED – 1 ONLY

Tank capacity (Litre): 150

Tank inlet & Outlet threads: 1-1/2″

Connecting hose thread: 3/4″

Pressure capacity (kPa / PSI): 1100 / 160

Tank diameter (mm): 420

Overall height dimension (mm): 1550

- Manufactured to AS1210-3 and supplied with manufacturer’s data report

- Supplied as standard with safety valve, pressure gauge and manual condensate drain

- Finished in industrial grade enamel

- Custom build and horizontal air receivers available on request

Razorweld 200P – DC TIG & ARC Inverter Welder-High Frequency

- Latest IGBT Inverter Technology

- Digital Weld Program Sequence Control

- DC TIG (DC tungsten inert gas welding)

- HF Arc Ignition (prevents tungsten inclusion & tungsten damage)

- Adjustable Pulse Frequency 0.5 – 200Hz

- Peak Current, Base Current and Pulse Width Adjustment

- 2/4T Trigger + Spot Time Adjustment

- Start & Final Current Adjustment

- Pre and Post Gas Flow Adjustment

- Up and Down Slope Adjustment

- Remote Torch Amp Control

- MMA (stick electrode)

- Arc Ignition

- Arc Force

- Thermal Overload Protection

- Generator compatible (recommend 9.0KVA 230V)

BG8-915 – Industrial Bench Grinder with Linishing Attachment 200mm 1HP

MINIMAL USE – 1 ONLY

- True 1hp motor for maximum torque

- Unique adjustable oval eye shields with magnifying glass

- Pre-load bearings (no end play)

- Heavy sheet metal wheel guards

- Includes a 915 x 50mm linishing attachment fittedIncludes

- Cast tool rests

- Wheel dresser

- Water tray

- Work light

SHST-1.6HD – Shrinker Stretcher – Heavy Duty

MINIMAL USE (TEST ONLY) – 1 ONLY

- 1.6mm mild steel capacity

- Shrinks metal for inside bends

- Stretches metal for outside bends

- Works on flanges up to 205mm wide

- Easy foot pedal operation

- Strong steel stand provides an ideal working heightIncludes

- 1 x set of shrinking dies

- 1 x set of stretching dies

No. 6 – Bench Vice – Cast Iron

150mm ENGINEERS BENCH VICE

NEVER USED – 1 ONLY

Rigid and robust, the body and sliding jaw are cast from close grained grey iron which is CNC manufactured on all friction surfaces for a smooth reliable action.

The jaws, handle and main screw are steel, the latter having a two-start rolled acme thread to speed the jaws from fully closed to fully open with a minimum of winding.

Here you can create the content that will be used within the module.

FLA-2T – Forklift Jib Attachment

MINIMAL USE – 1 ONLY

Lifting capacity (W.L.L.) (Tonne): 2

Width (mm): 635

Safety chain length (mm): 1200

Fork tyne location sports *W x H) (mm): 153 x 60

*Please note forklift capacity must be rated W.L.L 2 Tonne (2000kg) or greater

Features

- T bar screw locks for fork tyne’s

- Swivel hook with latch

- Steel construction

- Complies with standard AS/NZS2359.1